Fracture Benchmark

All CFRAC participants are invited to contribute to a special fracture benchmark organized by Julien Réthoré. They are encouraged to present the results of their simulations in the benchmark session, which supplements the minisymposia. This presentation is not counted when the policy of one presentation per registered participant is applied.

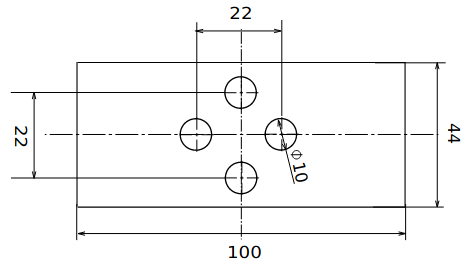

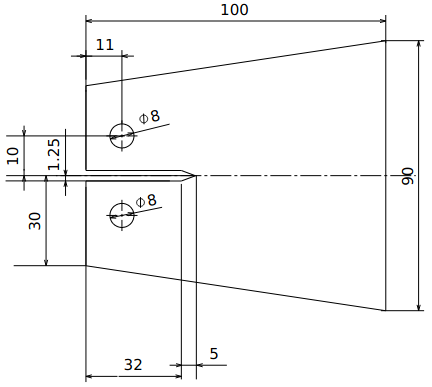

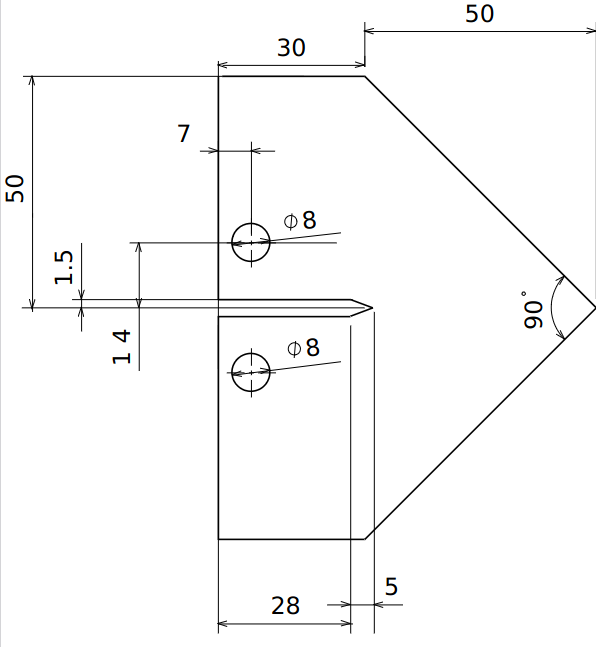

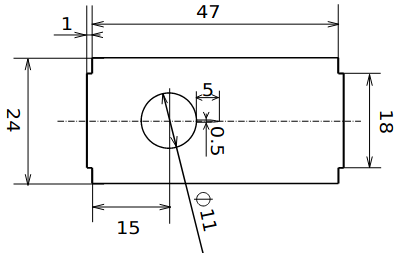

The proposed benchmark focuses on quasi-brittle failure of a Plexiglas plate. In total, four experiments have been performed and documented using high resolution imaging and full-field displacement measurement based on Digital Image Correlation (DIC). Two experiments will be used for calibration of model parameters, and the other two experiments should then be predicted.

Calibration

The samples are subjected to quasi-static loading. An extensive data set is provided for calibration purposes in the data repository (password cfrac2023). Our estimate of the nonzero coefficients of the linear elastic stiffness matrix for two-dimensional simulations is D12 = D21 = 1.17 GPa, D33 = 1.33 GPa (shear modulus), and D11 = D22 = D12 + 2*D33 = 3.83 GPa, assuming isotropy. If the simulation is performed under plane stress, this corresponds to Young’s modulus E=3.47 GPa and Poisson’s ratio nu=0.306.

Prediction

After calibration of their model using the provided experimental results, the participants can proceed to predictive simulation of the other two tests.

Reporting

The results should be collected and sent to the organizer (julien.rethore@ec-nantes.fr) in the form of csv files containing at least the evolution of the reaction force versus the prescribed displacement and, if available, also the crack length evolution. The force should be specified in N/m (to make the result independent of the specimen thickness) and the displacement and the crack length in mm. For TRIANGLE, the crack length should be measured from the left edge of the sample and for SCDC from the center of the hole.

The final results can be submitted until 15 June 2023. However, it would be very helpful if you can send us your results before 15 May 2023. If you cannot meet this first deadline, please let us know by email that you are planning a later submission, so that we have at least an idea about the expected number of benchmark presentations. This is important for preparation of the detailed conference program.